We're pleased to announce a new product for the trailer performance aftermarket is being released today.

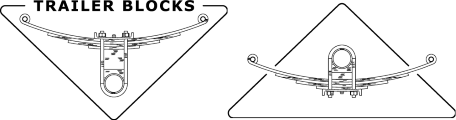

Lift/lowering blocks will now be available for 1-1/2" diameter square axles with a 1200-1800lb weight rating commonly found on small craft, jet ski, and light utility trailers.

Kits can be found in the 1200lb-1800lb square axle collection.

This new product lineup is for light duty trailers needing a change in ride height. Common applications include lifting the trailer to accommodate larger wheels and tires.

We also understand that some customers with off-road requirements cannot adjust their hitch to tow small trailers in a level configuration. These lift/lowering Trailer Blocks can be used to address this.

As seen with this jon boat trailer, ATV/UTV off-road tires have been retrofitted with the new Trailer Blocks in a lift configuration providing greater tire to fender clearance and back-county performance.

Let us know what you think of this new addition to the lift/lowering product line-up. As always we're looking for feedback from our customers as to what new products they would like to see.

-Thanks for reading from Team Trailer Blocks,