Trailer Tech: Spring has Sprung Checklist

Welcome back to Trailer Tech!

The snow is melting and the days are getting warmer. Spring is here and it’s time to get back on the road. With the weather improving, now is the perfect time to perform some maintenance and any necessary modifications to your trailer to get ready for spring and summer road trips. During our performance voyages and other road trips, we made some observations on the checks needed to keep our trailer running smoothly.

GENERAL TIPS

- Begin with a basic visual check and make sure everything on your trailer is in good working order. An obvious tip perhaps, but it can be easy to not pay enough attention to this step. This includes anything that actuates or illuminates

- Assess the general condition of the axle

- Grease the axle bearing nipples or repack your bearings to keep them running cool and smooth. Check with your axle manufacturer for model specific maintenance requirements

- Check for wear and proper impedance on electric brake magnets. Magnets that test outside of the manufacturer specified impedance should be replaced

- Remember that you will need marine-grade grease for boat trailers backing in and out of the water up and down boat ramps

- Check brake hydraulics (if equipped) for leaks. Change the hydraulic fluid per the manufacturer's recommended schedule. Ensure the parking brake and breakaway cables are not frayed or properly connected

- Check brakes for uneven wear or scoring, proper mounting and ensure proper actuation. If the brake pads or shoes are approaching the linings, they should be replaced

- Check the lug nut torque and ensure that your wheels are not falling off! Apply a thin layer of anti-seize to the studs

- Check the tires for bulges, cuts, nails and heavy/uneven wear

- Tire pressure checks reduce tire wear and the use of nitrogen will result in lessened loss of pressure over time

- Prevent corrosion with rust inhibitor products and touch up paint. Remember that a little bit goes a long way! Thick applications of rocker guard, rust inhibitor, undercoat, anti-seize and paint allows moisture to build up over time and rust the underlying component.

SUSPENSION

- Water has the unique characteristic of expanding when changing from a liquid to a solid state, and during a freeze thaw cycle, moisture in between the leaves in a leaf spring pack can loosen and shift the leaves. Even if your trailer sat idle for most of the winter, it is important to check that the leaf pack is tight and straight and that the spring clips are free of rust and tight.

- Some springs require additional attention during maintenance in the shackle and bushing departments due to comparatively higher complexity when mounting. Many modern double eye springs use a nylon, bronze, or polyurethane bushing. Worn bushings will appear frayed or cracked towards the outer edges and become worn down and thin towards the center, developing groves from wear. Bronze bushings require wet bolts that need to be greased.

- Applying a thin layer of grease anywhere there is contact between shackle straps and spring hangers ensures the spring can flex freely without binding.

- Check spring seats shackle straps and hangers for cracks in the welds that secure them to the frame or axle. Check for bends and deformations and excessive wear around bolt holes. Replace as necessary and prevent corrosion with rust inhibitor products and touch up paint.

- Ensure shock absorbers provide adequate resistance, and replace if they feel loose or leaky. Ensure shock absorber and rubberized equalizer bushings are pliable and are not cracked or hard.

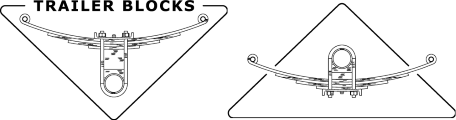

U-BOLTS/TIE PLATES

- During installation, U-bolts should be torqued down only once. Reusing them reduces clamping force by 55%.

- Torque should be checked/re-checked after road-testing and some use. If your leaf spring pack, leaves, or Trailer Blocks have shifted, your U-bolt torque may be incorrect and should be checked.

- Always ensure they are SAE-Grade 8 with rolled thread

- Prevent corrosion with a thin layer of anti-seize on U-bolt threads. This can help to facilitate re-torque. Use a thin application of rust inhibitor on tie plates and U-bolt arms as needed.

- Read our blog about Reusing Tie Plates | Trailer Blocks: bit.ly/2Vpr9xI

We hope the tips outlined thus far have been helpful in guiding your seasonal checks in a effective way. It is important to remember that your trailer may have special or varying equipment that needs additional maintenance and checking. Always consult your owner’s manual for exacting recommendations. If you are not mechanically inclined or equipped to carry out the seasonal checks you should consult a qualified mechanic with experience working on trailers.

If you feel we’ve missed anything or would like to add to the discussion, please leave a comment below or contact us at contact@trailerblocks.com if you have a question for us specifically.

Thanks for reading.