TrailerTech: Aluminum vs. Solid Steel

Welcome back for our latest TrailerTech article!

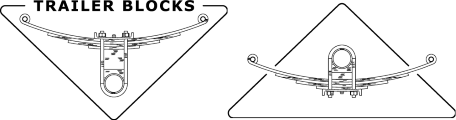

Today, we’re taking a look at something that’s been brought to our attention before: why do we use 6061-T6 aluminum for our lift/lowering blocks as opposed to solid steel? This is not the first time alternative materials and composition methods for Trailer Blocks have been discussed, but since we’ve had some questions regarding the use of solid steel for blocks, we’d like to reexamine the issue here.

A Trailer Block fabricated from solid steel such as billet steel, has a compressive strength capability as high and depending on the alloy, higher than a Trailer Block fabricated from 6061-T6 aluminum. We can see strength is certainly not the issue, but what about weight? A Trailer Block composed of solid steel will add a relatively large amount of unsprung mass to the axle. When a leaf spring breaks, this can often be caused by a sudden unloading of weight, such as when a wheel drops into a hole in the road. In a situation such as this, unsprung mass is often the biggest culprit. A large increase in unsprung mass caused by a solid steel block would require a custom spring designed to accommodate the extra mass. If the trailer is not equipped with proper shock absorbers, the effect can be even greater, causing more suspension oscillation over bumps. To reduce the amount of unsprung mass, aluminum remains the ideal alloy to fit the technical demands of the application due to its strength to weight ratio and corrosion resistance.

We also recommend that you consider the following points when lifting or lowering your trailer with our signature Trailer Blocks:

- Use only solid billet aluminum lift/lowering Trailer Blocks that will resist crushing forces

- Use only SAE Grade 8 U-bolts with rolled threads.

- Do NOT re-use U-bolts under any circumstances. When reused, U-bolt clamping force is reduced by over 55%, even though your torque wrench reading is identical. U-bolts should never be used with lock washers, as they will fatigue and eventually break.

- U-Bolts MUST be torqued to the manufacturer’s recommendation. If U-bolts are not torqued sufficiently, they may loosen and if they are over-torqued, they can exceed their maximum tensile strength and break.

- Carefully asses tie plate wear. It’s generally a good idea to replace tie plates every time you replace U-bolts. Ensure the tie plate is strong enough to support the required U-bolt.

- Always ensure that springs, spring clip, shackles, suspension bolts, bushings and mounting brackets are in good, lubricated condition (up-to-date in the case of a dry system) and are corrosion-free.

Thanks for reading.