Trailer Tech: Importance of Wheel Balancing

Welcome back to Trailer Tech

Today, we’re taking a look at the importance of wheel balancing, the different types of balancing and how this applies to your trailer. It is sometimes thought that there is no need to balance your trailer’s tires, but we’ll show you why it’s a good idea to do so.

Wheel balancing is a critical aspect of any vehicle’s correct operation at speed, as doing so will reduce tire wear and component wear caused by vibrations in the running gear. In extreme cases, tires can bounce down the road due to excessive vibration. It is important to note that not all trailer’s wheels come balanced from the factory or dealership.

Wheel balancing generally comes in 2 forms. "Off-vehicle" wheel balancing is the most fundamental in that the rim and tire are removed and mounted on a balancing machine, then reinstalled on the vehicle. Off-vehicle balancing is certainly more common and a necessity in any tire shop as an unbalanced tire greatly reduces tire life. This method does not balance the axle and hub assembly to the rim and tire assembly and is thus more suited to short distance and low or moderate speed as well as off road usage.

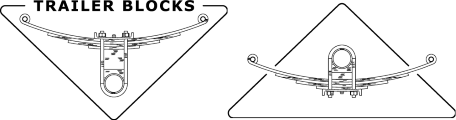

The minimum requirement in wheel balancing

Balancing the tire to the rim as well as the rim to the hub assembly requires "on-vehicle" balancing, generally performed after, and in addition to the off-vehicle wheel balancing described above. Even though on-vehicle balancing often requires a shop with special equipment and training; it can help reduce running gear vibrations coming from inboard sources with most noticeable gains visible in long distance and highway driving as well as in longer axle and hub assembly life.

Balancing heavy hub assemblies to the rim and tire can improve ride quality

Please contact us with your Trailer Tech questions, we're happy to help. Thanks for reading!