Instructions

The onus is on you, the installer, to BE SAFE when outfitting/modifying your trailer. These installation instructions are for informational purposes only. Consult a mechanic if you have any uncertainty about installation procedures. Be sure to have your trailer inspected with the suspension loaded, after installation is complete. Check clearances and ensure your trailer's suspension is operating correctly. Trailer Blocks components are sold in many countries and sometimes local laws can limit modification of road-going trailers, be sure to check your local rules.

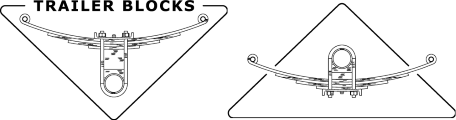

The difference between "lift" and "lower"

Axles in a lowered configuration mount above the spring (through the gap between the frame and the spring). Axles in a lifted configuration mount below the spring. The lowered configuration is pictured in the foreground of the image below, while the lifted configuration is pictured in the background.

Warning! - Cambered Axles

Caution must be taken when changing from lower to lift or vice versa. Many trailer axles have a slight arc in them, such as the one pictured above. These are called cambered axles. Cambered axles compensate for too much negative camber (where the bottom of the wheel is farther out than the top) when the axle is loaded. The unloaded axle is given slightly positive camber so that when loaded the axle is straight maximizing tire contact area.

If a cambered axle is rotated 180 degrees when moving the axle from over the spring to under the spring or vice versa, it will exhibit positive camber when loaded (the top of the wheel is farther out than the bottom). This is extremely unsafe as it reduces tire contact area, reducing grip.

For this reason, spring seats are required opposite each other so that the axle can remain in the same orientation when transitioning it from over the spring to under the spring or vice versa. If your axle only comes with 2 spring seats and has an arc, over/under conversion kits are available that add 2 spring seats to the axle.

U-bolts

The primary function of the u-bolt is to provide the clamping force required to securely attach the spring to the axle assembly.

U-Bolts come in various sizes, the chart below shows common axle ratings and the u-bolts required for each.

Note that the u-bolt lengths described above are desired. Rod stock generally comes in 2" increments and the bent final product may require trimming. Diameter, width and grade should be exact.

Warning! DO NOT re-use u-bolts under any circumstance. If re-used, u-bolt clamping force is reduced by over 55% even though your torque wrench reading is identical. U-bolts should never be used with lock washers, they will fatigue, break and fall off.

U-Bolts must be torqued to the manufacturer recommendation. If u-bolts are under-torqued, they may loosen. If u-bolts are over-torqued, they can exceed their ultimate tensile strength and break.

Installation Steps

- Jack up trailer and secure on adequate capacity jack stands. Follow the trailer manufacturer's recommendations for lifting and supporting the unit. Do not lift or place supports on any part of the suspension system. CAUTION: Never crawl under your trailer unless it is resting on properly placed jack stands.

- Remove wheels and tires from hubs.

- Mark top of axle with paint or chalk for reference during re-installation.

- Disconnect brake wires from the harness at the connectors.

- Support axle.

- Remove U-bolt nuts, U-bolts and tie plates. Discard U-bolt nuts and U-bolts.

- Remove axle.

- Inspect hangers, spring seats, bushings, spring eye bolts, under side of trailer frame and all welds for wear. Correct if necessary.

- Insert lift/lowering blocks in the desired location. Refer to the photos above in "the different between lift and lower" if you need help. Place axle in new position, with top of axle (previously marked) still up. Proper axle placement is important for brake operation and vehicle stability. Please review the cambered axle warning above for more information.

- Reattach springs using NEW lubricated U-bolts, nuts, washers. Tie plates can be re-used if in good condition. Torque U-bolt nuts to the value specified on the information stuffer included with your order. (Or until bending of the tie plate or U-bolt arms becomes visually apparent.)

- Reattach axle(s). Ensure axle(s) are square to frame and aligned to hitch.

- Reattach brake wires using new corrosion resistant connectors.

- Verify proper brake current draw (typically 3.0 amps per magnet.)

- Reinstall wheel and tire, lower vehicle to ground. Check for proper braking function.

- Roadtest the vehicle. Re-check torque on the U-bolts & lug nuts. Apply the Trailer Blocks equipment identification decal in a highly visible area.