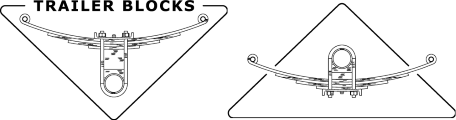

TrailerTech: Trailer Blocks Safety Questions and Tips

Welcome to a new installment of TrailerTech! Today, we’ll take a look at some questions and comments lately that we’d like to address.

The proper installation of our products is of major concern for us and as such, we actively strive to aid our customers with any technical or safety-focused questions they may have. Inquiries such as “Are lift/lowering blocks safe for use on my trailer?” have made their way into our inbox and we’d like to offer some information and tips on some common concerns we’ve seen raised.

Changes in Vehicle Height

Changing the height of a vehicle will always change vehicle dynamics, period. We have assembled some tips for lifting and lowering your trailer.

Lifting: Despite raising the trailer’s center of gravity, it’s important to note that a level trailer is far more stable than a low, but improperly leveled trailer. 1”- 4” blocks will keep the change in overall ride height small and minimize the added mechanical advantage the axle has on the suspension. A rule-of-thumb to use when working out an appropriate lift is to keep the ride height change within 5% of the overall vehicle height. For example, adding a 3” lift to a 10 ft. tall travel trailer would result in a 2.5% change in the ride height, which is acceptable.

Lowering: When lowering a trailer, clearance becomes the major factor. Once again, 1”- 4” blocks will minimize the added mechanical advantage the axle has on the suspension. Generally speaking, a standard trailer suspension will accommodate 1” – 2” blocks without modification. When lowering a trailer 2.5” – 4” it is advisable to switch to a standard 4” drop axle, and adjust up or down with blocks and axle placement (above or below the spring) to achieve the desired ride height.

While discussing changes in vehicle height, we talked about the added mechanical advantage the axle has on the suspension with the additions of lift/lowering blocks. This can be broken down into two categories: axle wrap and wheel scrubbing, explained below.

Wheel Scrubbing (lateral twisting)

Wheel scrub is fairly common in tandem axle situations. Since the center of mass is between the axles, maneuvering a trailer in a tight area causes it to rotate on its axles. One axle shifts to the left and one to the right, causing the axles to appear misaligned. This situation is present on trailers with or without modifications to the ride height. Wheel scrub can look unnerving, but leaf spring suspension is well suited to dealing with this due to its excellent lateral rigidity. It’s important to remember that the forces the suspension encounters under hard braking are actually greater than those encountered during wheel lockup or wheel scrub. A locked wheel behaves in a similar manner to a wheel in scrub, in that they are both not rotating with respect to the road with low friction between the contact patch on the tire and the road surface.

Axle Wrap (longitudinal twisting)

Axle wrap, or longitudinal twisting of the leaf spring occurs when torque is applied to the suspension, forward or aft, in the form of acceleration or braking. It is the leading cause of concern when using blocks on a driven axle or, the front axle of a vehicle, as the block can “squirt” out under extreme torque. The axle is not driven on a trailer and the condition known as axle wrap does not occur under acceleration under normal circumstances. But trailers have brakes, this means the axle is subjected to axle wrap under braking. Tires on an axle that is not driven and not the front axle of the vehicle, experience wheel lock-up before axle wrap overwhelms the spring. This means that the maximum amount of axle wrap occurs at impending wheel lockup. The leaf spring by design is well suited to absorbing forces acting longitudinally on the spring. Adding suspension blocks to a trailer will increase the effects of axle wrap caused by braking. Increases in axle wrap, wheel scrub and changes in vehicle height, are non-issues when adding lift and lowering blocks to trailers using axles with a gross axle weight rating (GAWR) of 3000lb to 7000lb as long as you follow some simple guidelines:

- Use only SAE Grade 8 U-bolts with rolled thread.

- DO NOT re-use U-bolts under any circumstance. If re-used, U-bolt clamping force is reduced by over 55% even though your torque wrench reading is identical. U-bolts should never be used with lock washers, they will fatigue, break and fall off.

- U-bolts must be torqued to the manufacturer recommendation. If U-bolts are under-torqued, they may loosen. If U-bolts are over-torqued, they can exceed their ultimate tensile strength and break.

- Carefully assess tie plate wear, it is a good idea to replace tie plates every time you replace U-bolts. Ensure the tie plate is strong enough to support the required U-bolt.

- Use only solid billet aluminum Trailer Blocks that will resist crushing forces.

- Always ensure that springs, spring clips, shackles, suspension bolts, bushings, and mounting brackets are in good, lubricated condition (up to date in the case of a dry system) and are free from corrosion.

Maintaining these components with regular upkeep is as important as any regular trailer maintenance routine with or without ride height modifications.

By following the above guidelines, lifting or lowering your trailer with blocks is a safe and effective way to modify the ride height of your leaf spring trailer. It ensures your rig is kept level, and it opens up a diverse selection of wheel and tire options to improve on and off-road performance.

We got hope this helps clears up any questions or concerns. If you have any technical issues of your own you’d like us to talk about, please send them to: contact@trailerblocks.com

More entries and updates coming soon.